Case Study - Clade Engineering Solutions

About Clade Engineering Solutions

Clade Engineering Solutions is a UK-based industrial engineering company specialising in industrial heat pump assets and refrigeration. They offer manufacturing, installation, and aftercare maintenance and support services. With over 30 years of experience, Clade is an industry leader in energy transformation using natural refrigerants. Their heat pumps help businesses reduce their carbon footprint, with CO2 and Hydrocarbon models available. Clade remains at the forefront of heat pump technology with digital control/monitoring platforms and services.

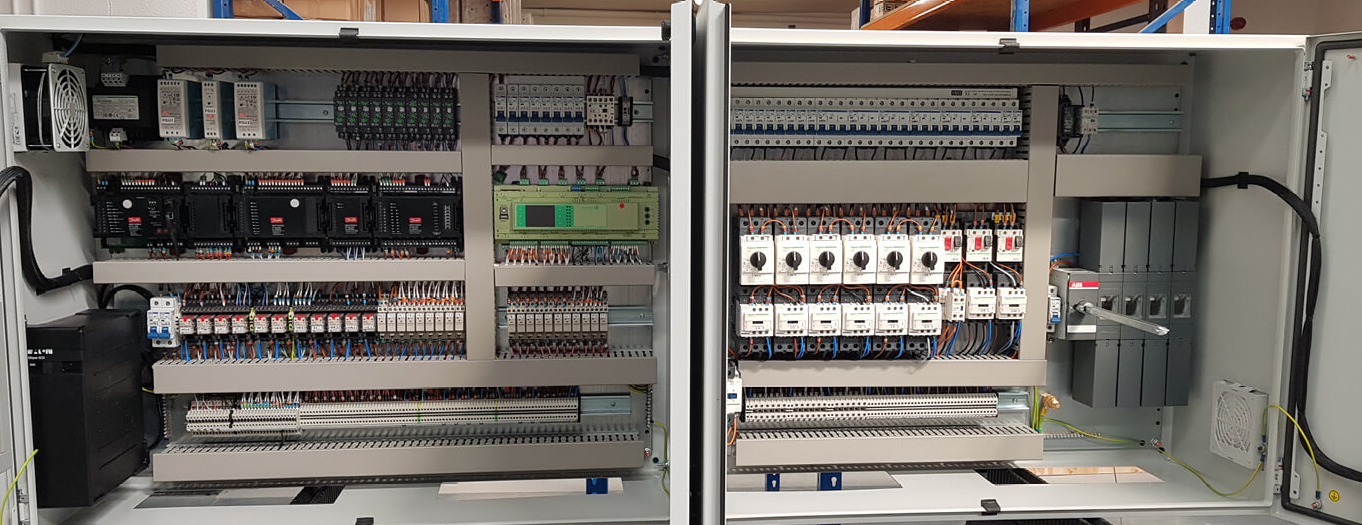

Discover how GB Controls provided heat pump control panels to support Clade’s innovative solutions below.

Project in Focus

How did this project come about? Is it the first time you have worked with this company?

Clade Engineering Solutions is a long-standing customer of GB Controls, and we have collaborated on numerous large-scale projects together on several big projects over the years, mainly focused on industrial refrigeration systems for supermarkets and cold storage. This project was initiated towards the end of 2021 when we received an inquiry from Clade to build heat pump control panels for various sites across the UK.

How long did the project take from start to finish?

The initial order of heat pump control panels was dated for delivery starting in March 2022 and running through to June 2022. However, this is an ongoing project, and Clade has continued to order the panels as new sites have come online. A big redesign was also carried out in November 2022 to incorporate feedback from the initial installations.

What were the main challenges?

GB Controls designed a heat pump system for Clade Engineering Solutions that uses a unique combination of two low Global Warming Potential (GWP) refrigerants, R290 and R600, in a cascade configuration to optimise the system’s Coefficient of Performance (COP). However, these refrigerants are flammable, which presents safety concerns. To mitigate the risks, GB Controls incorporated a control strategy that allows for the complete shutdown of the system in the event of a leak. We took into consideration the potential ignition hazard posed by the electrical components in the control panel, and implemented additional safety measures to ensure the system is completely secure.

The project was also affected by significant supply chain obstacles, which were chiefly attributed to the global scarcity of goods resulting from the COVID-19 pandemic. This shortage posed significant challenges in procuring certain components, such as motor starters, contactors, safety relays, pumps, and fans, both on the electrical and mechanical fronts for the control panels. Regrettably, the extended lead times for these components were outside the delivery timeline for the project, causing further delays.

How did you overcome these challenges and what was the client’s reaction?

Despite encountering several supply issues, GB Controls implemented effective solutions by sourcing components from alternative suppliers, albeit at a higher cost. In cases where sourcing was infeasible, we utilised alternative products with identical functionality. Nonetheless, we had to modify the design to accommodate an alternative fan type as the originally specified fans were not indefinitely available.

GB Controls helped move the system’s shutdown from a separate panel to the main control panel, simplifying installation and reducing cable runs. GB Controls’ 10″ web-based HMI was added to allow for user monitoring, diagnostics, and trend graph creation.

By collaborating with Clade Engineering Solutions, we successfully revised the design to incorporate a variety of alternative components, ensuring timely delivery and superior quality of heat pumps. Our clients have provided us with positive feedback, highlighting our adaptability to incorporate emerging technologies and problem-solving skills in the face of challenging issues.

How do you think the industry will change over the next few years and how are we adapting to this change?

- Shift to Natural Refrigerants: There is an increasing demand for natural refrigerants such as CO2, ammonia, and hydrocarbons due to their low GWP (Global Warming Potential) and environmental friendliness. Heat pump systems using natural refrigerants are expected to become more popular, replacing systems that use synthetic refrigerants.

- Energy Efficiency: With the growing demand for energy-efficient heating and cooling solutions, heat pumps are becoming increasingly popular in residential, commercial, and industrial applications. Heat pump technology is expected to continue to improve, with a focus on increasing efficiency and reducing energy consumption.

- Smart Controls and Monitoring: Advances in technology are making it easier to monitor and control heat pump systems remotely. Smart controls and monitoring systems can optimise energy consumption, reduce maintenance costs, and improve system performance.

Was the project a success?

The project was not only completed on time, but with flying colours! Our team delivered exceptional results that not only met, but exceeded Clade Engineering Solutions’ expectations.

GB Controls is committed to staying ahead of the curve by continuously building its knowledge of heat pump systems and adopting innovative solutions to meet the evolving needs of its clients. This project has been an excellent learning opportunity for the team, and they are confident in their ability to deliver cost-effective, high-quality solutions that meet the unique needs of each customer.

Touch Screen Control Panels

If you’re looking to modernise your systems and enhance your capabilities, then get in touch with the GB Controls team.

We can assist with a variety of requirements to best suit your business or organisation’s needs.

To find out more information, contact one of our experts by phone or complete the enquiry form below.

Bespoke Control Systems

GB Controls creates bespoke control panels to cater for a wide variety of requirements across a range of sectors.

Get in touch with us by calling, emailing or filling out or enquiry form

Opening Hours:

Monday – Thursday (08:00 – 17:00)

Friday (08:30 – 15:00)

Saturday & Sunday (CLOSED)