GB Controls, a leading provider of electrical control systems, embarked on a

transformative journey from a non-automated CAD package to adopting the

latest state of the art WSCAD software.

GB Controls has been at the forefront of delivering innovative control solutions

for industrial applications for almost 40 years. Despite their expertise, the

company faced challenges inherent in relying solely on a low-level CAD package,

including prolonged design cycles, scalability, and increased risk of errors.

GB Controls adopts WSCAD software solution

Time-Intensive Design Process: The existing CAD package consumed valuable

time and resources, hindering the company’s ability to meet project deadlines

and customer demands promptly.

Inflexibility in Design Modifications: Any alterations or revisions to required

extensive rework, leading to delays and inefficiencies in the design process.

Collaboration Bottlenecks: Sharing and collaborating on drawings proved

cumbersome, often resulting in miscommunication and coordination challenges

among team members.

Embarking on cutting edge WSCAD technology

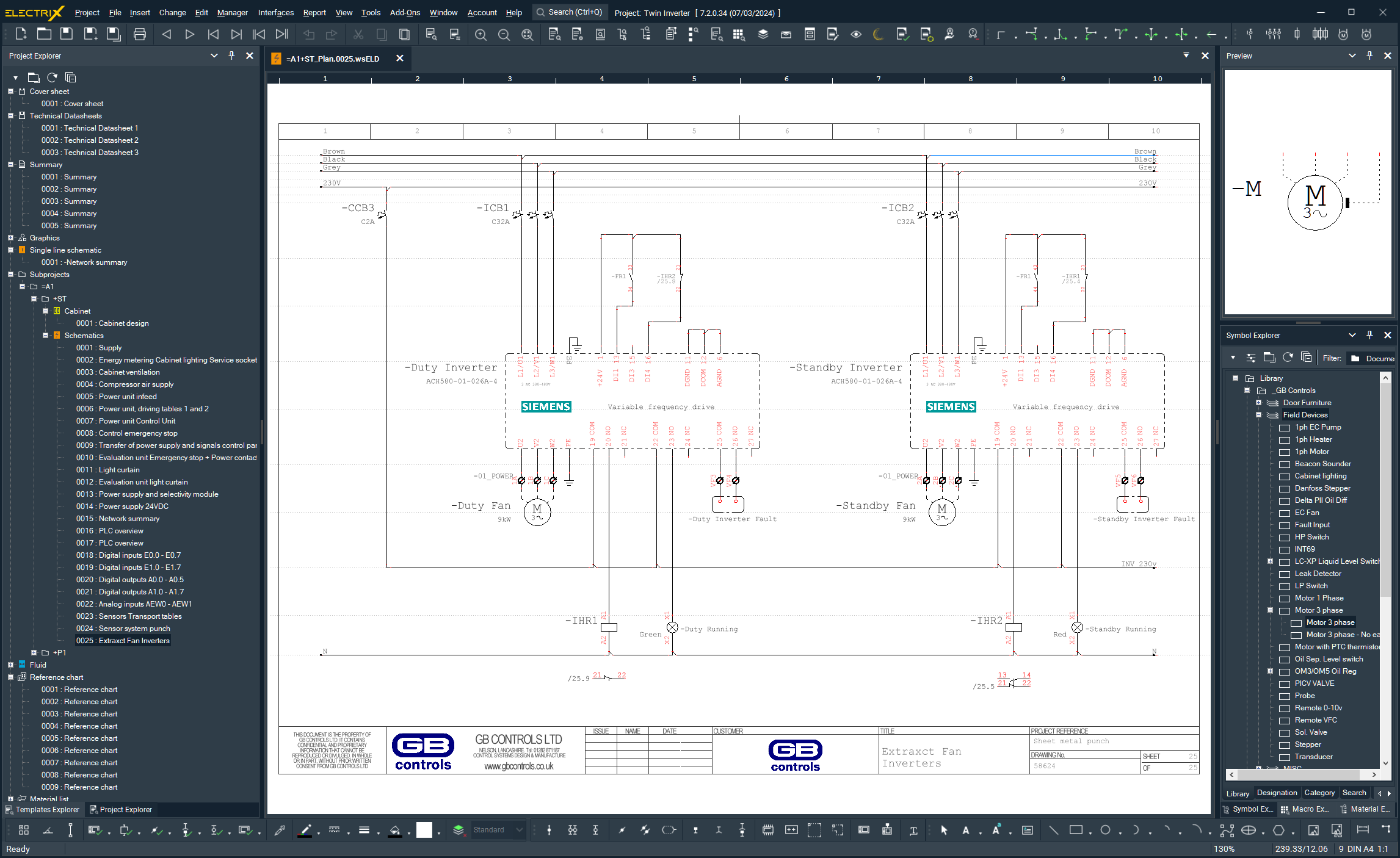

To address these challenges, GB Controls made the strategic decision to transition to WS-CAD software. After thorough evaluation, WSCAD was chosen for its advanced features, intuitive interface, and seamless integration capabilities with other engineering tools used by the company.

GB Controls sees huge benefits in WSCAD design for their control systems

Streamlined Design Process: WSCAD significantly accelerated the design

process at GB Controls, allowing engineers to create intricate control system

layouts in a fraction of the time compared to the existing CAD package.

Enhanced Design Accuracy: The precision tools and automated features of WSCAD ensured greater accuracy in design, minimizing errors and reducing the

need for extensive rework.

Improved Collaboration: WSCAD’s collaborative features facilitated real-time

sharing and editing of designs among team members, fostering better

communication and coordination throughout the design process.

Increased Design Flexibility: With WSCAD’s parametric modelling capabilities,

engineers at GB Controls could explore various design iterations quickly,

enabling them to adapt to evolving project requirements with ease.

Cost-Efficiency: By streamlining the design process, minimizing errors, and reducing rework, WSCAD helped GB Controls optimize resource utilization and

lower overall project costs, ultimately improving profitability.

A major step forward for GB Controls

The transition from manual drawing to WSCAD marked a significant milestone in GB Controls journey towards innovation and efficiency. By embracing modern CAD technology, the company not only overcame longstanding design challenges but also positioned itself as a frontrunner in delivering high-quality, cost-effective control solutions to its clients. This strategic investment in WSCAD has laid a strong foundation for future growth and continued success at GB Controls.

Find Out More About GB Controls

GB Controls has over 3 decades of experience and is proud to work with businesses and organisations up and down the United Kingdom and around the globe with their control panel needs.

Embarking on cutting edge technology from CAD Designed control systems to Bluetooth technology for monitoring GB Controls. Get in touch with our sales team for further information by calling 01282 871187 or alternatively, you can reach out to us online.